PE PVC single wall corrugated pipe machine

Single wall corrugated pipe machine developed by our company adopts gears to run modules and templates so as to realize water circulating cooling of the products, which ensures high-speed molding, even corrugation, smooth inner and outer pipe wall. These corrugated pipes are especially used in wires conduit pipe.It is mainly for the production of raw materials to PA.PP.PE small diameter single wall corrugated pipe. Die by the corresponding forming a homogeneous single-wall bellows products. Threading pipe for wire and cable, washing machinedrains, vacuum cleaners, ventilation pipe, prestressed concrete special tubes.

Inquire now

Add to cart

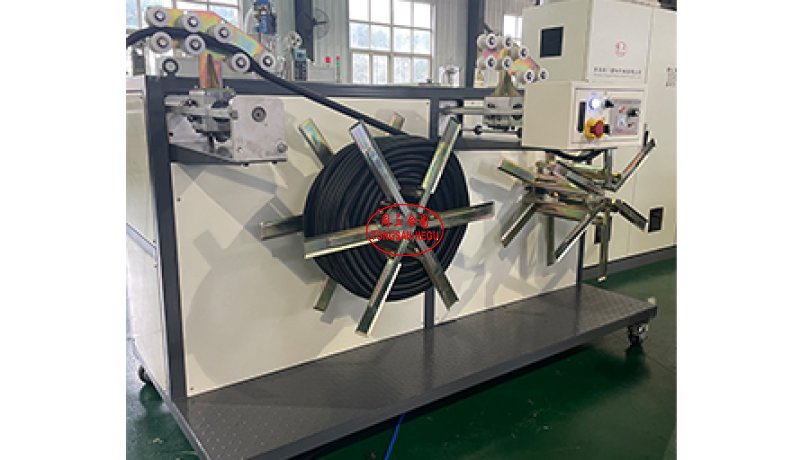

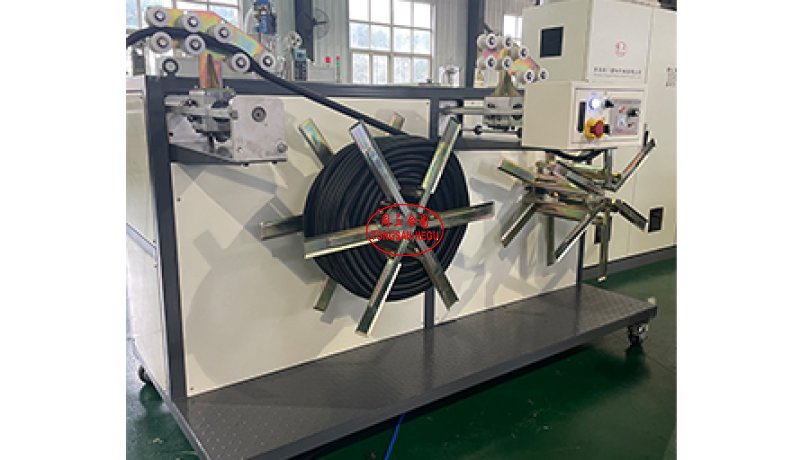

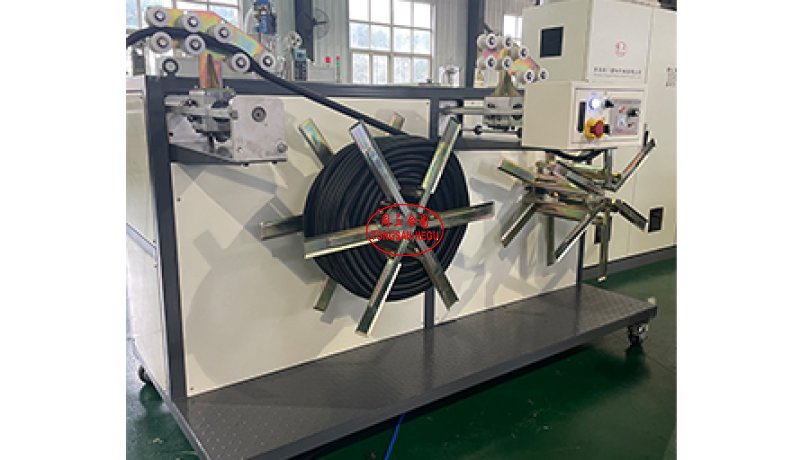

High speed single wall corrugated pipe extrusion line

The line speed can up to 30m/min. High speed forming machine equips with automatic lubrication system and closed forced water-cooling system to achieve high-speed production. The corrugated pipe molds includes single cavity molds and double cavity molds.

| Pipe diameter | Production speed | Extruder Model | Motor power |

| ID5-OD14mm | 10-20m/min | SJ45/28 | 7.5kw |

| ID12-OD50mm | 20-30m/min | SJ65/30 | 30kw |

Normal speed single wall corrugated pipe extrusion line

The line speed can up to 12m/min. The forming machine equips with air cooling system for cooling the molds and pipe.

| Pipe diameter | Production speed | Extruder Model | Motor power |

| ID5.5-OD16mm | 6-8m/min | SJ45/28 | 7.5kw |

| ID9-OD32mm | 5-12m/min | SJ50/30 | 15kw |

| ID12-OD50mm | 3-10m/min | SJ65/30 | 30kw |

| ID16-OD63mm | 3-10/min | SJ65/30 | 30kw |

| ID32-OD110mm | 3-8m/min | SJ75/30 | 37kw |

Vacuum forming single wall corrugated pipe extrusion line

The line can produce special design single wall corrugated pipe with vacuum forming mode. The forming machine equips with vacuum system. Specially designed for shisha hose/magic pipe/joint corrugated pipe.

| Pipe diameter | Production speed | Extruder Model | Motor power |

| ID9-OD32mm | 5-12m/min | SJ50/30 | 15kw |

| ID12-OD50mm | 3-10m/min | SJ65/30 | 30kw |

| ID32-OD110mm | 3-8m/min | SJ75/30 | 37kw |

The Final Product Application

Final product widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc.

The advantages of plastic corrugated pipes

1. With both rigid and flexible: has sufficient mechanical properties, at the same time has excellent flexibility.

2. Corrugated pipe has lighter weight, save material, lower energy consumption, cheaper advantage.

3. Corrugated pipes with smooth inner wall can reduce the flow resistance of liquid in the pipe, improve the transmission capacity.

4. Good performance in resistance to chemical corrosion, can resist the effect of alkali in the soil.

5. Pipe with corrugation form can increase the load resistance of the pipe to the soil. At the same time, do not affect its flexibility, so that it can be laid on the uneven ground continuously.

6. Easily to connect and good in tightness. Easily handing, easily install, reduce the labor intensity, reduce working period.

7. Wide using temperature range, inflaming retarding, self-extinguish, safety in use.

8. safe insulation, is an ideal material for the electric wire conduit.